Galvalume Steel Coils 0.43 Factory tsim cov aluzinc nrog rau qhov chaw muaj pes tsawg leeg yog 55% txhuas, 43.4% thiab 1.6% silicon kho ntawm 600 ℃.Aluzinc coils muaj qhov zoo nkauj nyiaj-dawb nto.

| Thickness | 0.12mm-3mm, raws li tus neeg yuav tsum tau muaj |

| Dav | 750mm-1250mm, raws li tus neeg yuav tsum tau muaj |

| Txuj | GBT2518-2008, ASTM A653, JIS G3302, EN 10142, thiab lwm yam |

| Khoom Qib | DX51D, SGCC, G300, G550, SGCH570 |

| AZ txheej | AZ30-AZ275g |

| Kev kho saum npoo | Passivation los yog Chromated, Daim tawv nqaij Pass, Roj los yog Unoiled, los yog Antifinger print |

| Spangle | Li qub (tsis-skinpassed) / Skinpassed / Regular / Minimized |

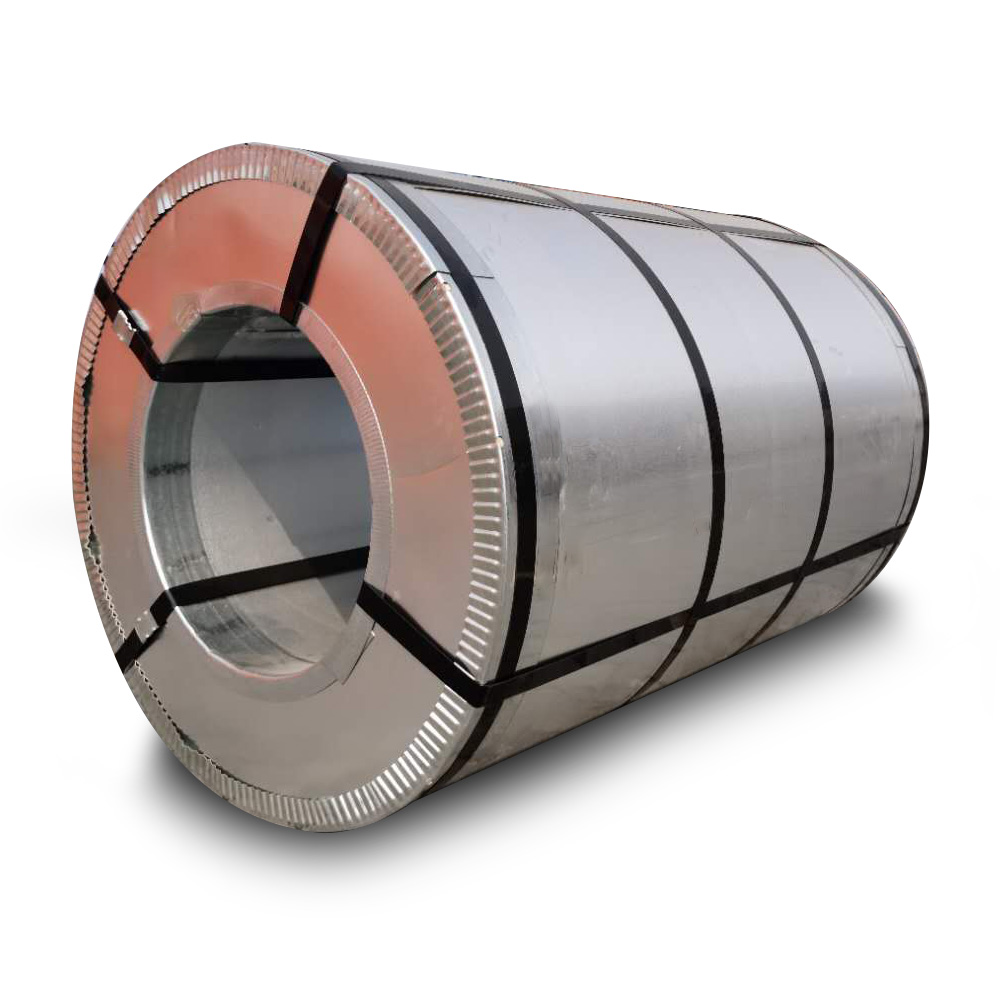

| Coil hnyav | 3-6 tons lossis raws li cov neeg siv khoom xav tau |

| Coil puab Diameter | 508/610mm los yog raws li koj qhov kev thov |

| Hardness | Mos hard (HRB60), Medidas nyuaj (HRB60-85), Full hard (HRB85-95) |

Khoom Zoo

1.Galvalume Az150 Chev muaj rau kev kho tshwj xeeb ntawm cov neeg siv khoom thov.

2.Perfect Corrosion Resistance.Lub neej kev pab cuam ntawm galvalume yog 3-6 zaug raws li ntev raws li ntawm galvanized nto.

3.Txoj kev ua haujlwm zoo.Ua tau raws li qhov yuav tsum tau ua ntawm yob ua, stamping, dabtsi yog khoov, ect.

4.Perfect Light Reflectivity.Lub peev xwm ntawm kev cuam tshuam lub teeb thiab cua sov yog ob zaug ntawm galvanizing.

5.Kev ua haujlwm kub zoo.Galvalume cov khoom tuaj yeem siv rau ntawm 315 degree Celsius rau lub sijhawm ntev yam tsis muaj xim.

6.Excellent adhesion ntawm cov xim.Yooj yim rau pleev xim thiab tuaj yeem pleev xim tsis muaj pretreatment thiab huab cua.

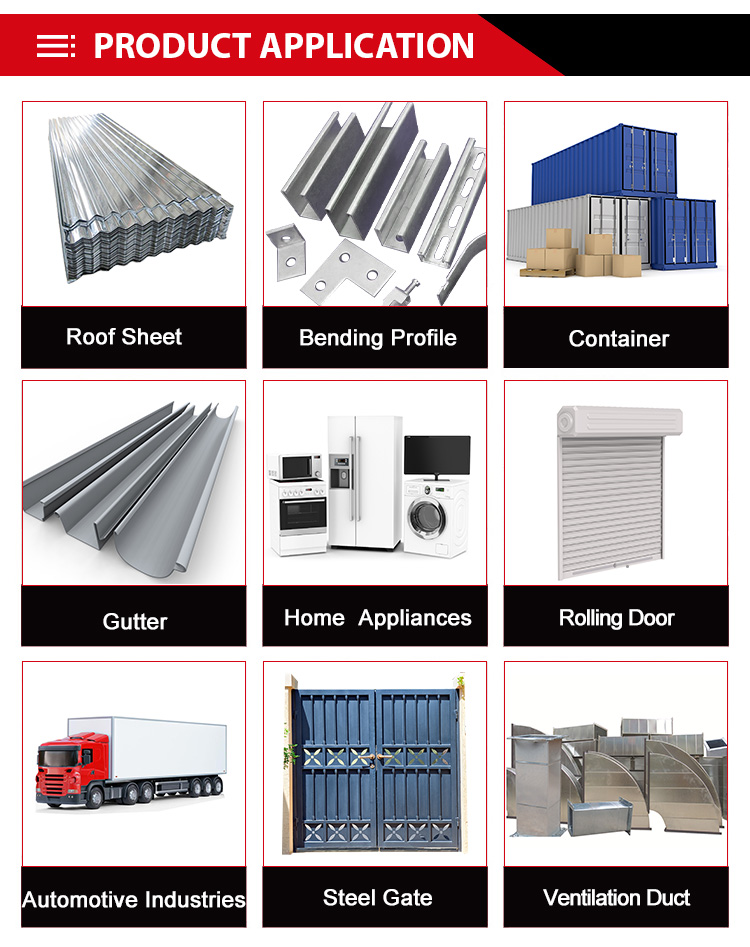

Daim ntawv thov

Galvalume steel coil muaj ntau yam kev siv, xws li ru tsev panels, phab ntsa vaj huam sib luag, lub teeb steel keels, cua sov radiators, tsheb lub cev, roj tso tsheb hlau luam, cable armored steel tapes, yas tsev cog khoom, granaries, shipping thawv, khoom siv hauv tsev thiab cov khoom siv, qhov cub. .Galvalume steel coils 0.43 manufacturers muab cov galvalume coil rau tawg-pov thawj steel siv, txheej npog ntawm cov cua txias thiab cua tshuab, hnub ci dej rhaub, ntim thawv rau cov khoom siv tshuaj, thiab xim phaj substrates, welded kav, steel qhov rais, txias-tsim steel cov ntaub ntawv nyob rau hauv metallurgical kev lag luam, thiab lwm yam., muaj ib tug dav daim ntawv thov prospect.

-

Galvalume Steel / Galvalum / Bobina Galvalume Tuam Tshoj

-

Aluzinc Steel Chev Galvalume AZ150 G550 DX51D 0 ...

-

Nqe Zoo 55% Aluzinc Galvalume GL Coated Stee ...

-

DX51D AZ GL Chev / Bobina De Galvalume / Zincalum...

-

Astm A792 Galvalume Hlau Chev Az150 Bobin De A ...

-

Prime Galvalume Steel Coils 0.19 hli Az50 Az70 A ...